De-mineralization Plant

De-Mineralization Plants

natural occurring water consists of many dissolved solids in dilute forms that are normally various kinds of salts. these solids are called TDS. Demineralization, also known as deionization, is a technique which removes minerals salts from water through the ion exchange method. both cation and anion are removed through this procedure which is also known as deionization. In other words, it is a wastewater treatment process.

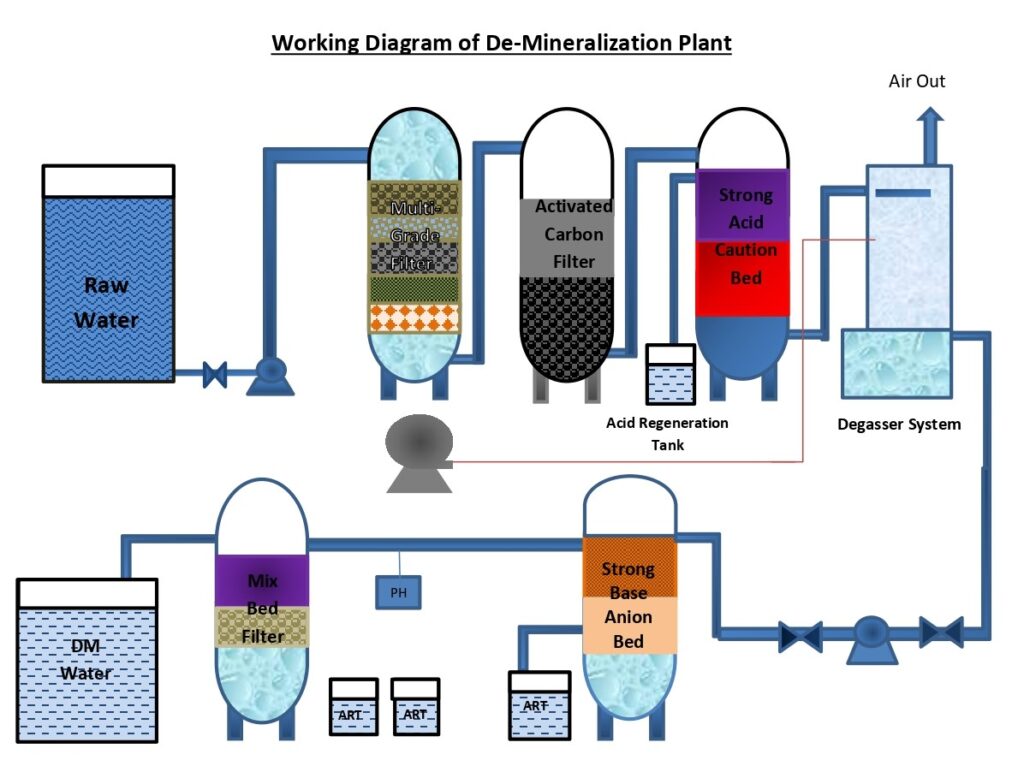

Working principle of De-Mineralization (DM) plant

Demineralization Water treatment is a physical technique. Ion exchange resins are in particular manufactured which assist to replace the mineral salts in water. There are two forms of resins – anion exchange and cation exchange resins. the previous resins release hydroxyl ions which are generally negatively charged ions. The cation resins release hydrogen ions which can be usually positively charged ions.

Type of De-mineralization processes

Two-Bed De-mineralization As the name indicates, this is a method with two vessels – one with a cation resin and the other with anion resin. First, water passes through a cation exchanger. each cation receives exchanged with equivalent hydrogen ions. This maintains the water electrically balanced. Water leaving the cation then passes through an anion exchange. The same principle is implemented here and anions are exchanged with hydroxyl ions

Mixed-Bed De-mineralization Here, instead of two different vessels, the cation and anion resins are mixed in a single pressure vessel. This technique is definitely considered to be more efficient than the two-bed plants but the regeneration method involved here is more complicated. The mixed-bed plants result in higher quality water than the two-bed plants. however, they are normally used when higher level of purification is needed. After the two-bed demineralization treatment, water is further polished by the mixed-bed process.

Working of De-mineralization plant

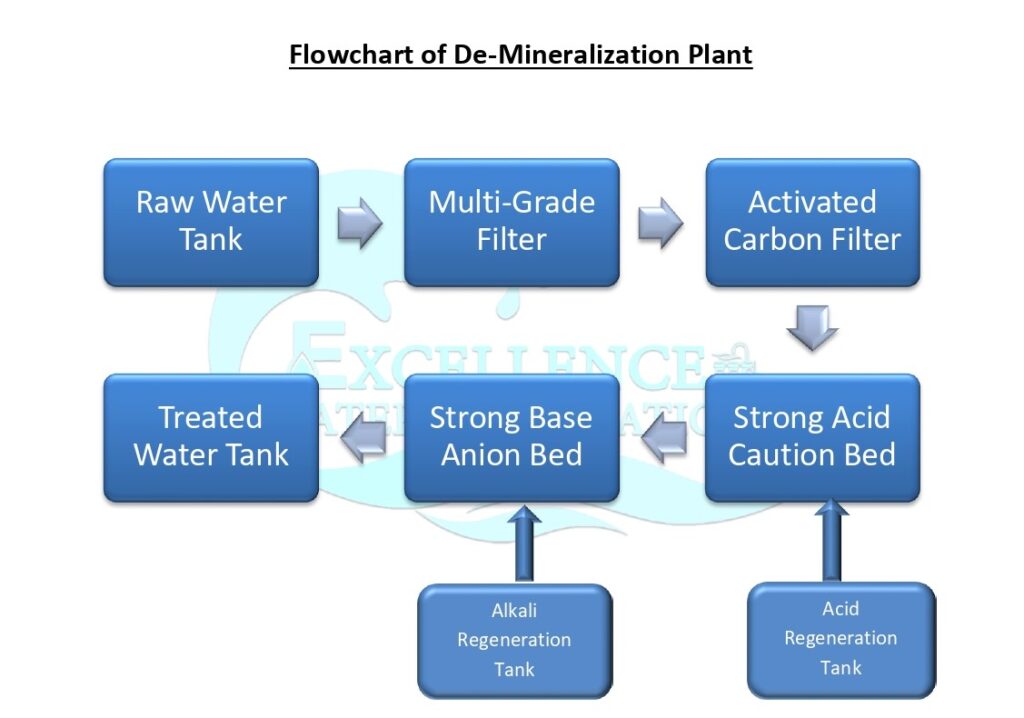

flowchart Of De-mineralization plant

Application of De-mineralization Plant

- Textiles industries

- Pharmaceuticals

- Swimming pools

- Boilers feed Water

- Automobile industries

- Chemical Industries, etc.

Advantages of De-mineralization Plant

- Simpler distribution and collection systems.

- Quick availability.

- Pre dispatch assembly check.

- User friendly, low maintenance and easy to install.

- Single valve operation as compared to the six valves in conventional filters

- Each operating step is clearly marked on the valve, thereby eliminating chances of error in the operating sequence.

Images